Fire

A1 has good to excellent fire resistance properties and can be used for projects with high fire resistance requirements. We have tested A1 in accordance with EN 13501-1 and ASTM E84-15b.

European classification

Classification of reaction to fire performance in accordance with EN 13501-1:2002. A1 (Acrylic One) LP01 and A1 Tri-axial Fabric:

B-s1,d0

Its reaction to fire behavior is classified : B

The classification to smoke production is : s1

The classification to flaming droplets / particles is : d0

Classification of reaction to fire performance in accordance with EN 13501-1:2007+A1:2009. A1 LP01 and A1 Tri-axial Fabric + sand (25% of mass A1):

A2-s1,d0

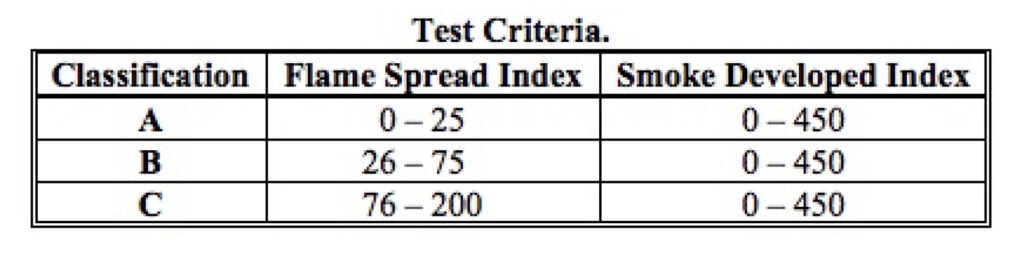

USA fire rating

Evaluation of the surface burning characteristics of a material

identified as A1 in accordance with ASTM E84-15b, standard test method for surface burning characteristics of building materials.

Flame Spread Index (FSI) : 20

Smoke Development Index (SDI) : 15

UV

UV has a strong influence on the durability of materials. 20+ year old A1 project in South Africa shows that (coated) A1 will withstand UV influence.

When an uncoated A1 object is exposed to (intensive) UV the very thin top layer of the A1 object will be affected (erosion) within a few months. This will mainly be noticeable by a change of the colour of the A1 object. After this initial period the erosion by UV will continue but at a very slow rate.

Adding sand to the A1 object (1 part A1 Liquid, 2 parts A1 Powder and 2 parts Quartz sand) will still result in an initial erosion of a very thin top layer but after this the added sand will almost stop the erosion process of the A1 object caused by UV.

For the best protection we advise applying layers of A1 Sealer PLUS to the A1 object as this layer will act as a barrier between the UV radiation and the A1. When you have used our A1 Sealer we recommend to apply a new layer after 3 years with our A1 Sealer PLUS. Other coating systems can be used as well if they are damp open (KEIM Soldalan) or the A1 object can release its moist at the backside of the A1 objects (for ventilated Cladding systems).

Water

Similar to many other materials, A1 will attract moist/water at a humidity rate above 90%.

An A1 object will release its water when placed in an environment with a lower humidity (below 70%) at a high speed as can be seen in graph 2. It only takes a few days to reach the levels at starting point.

Exposure of an A1 object to very high humidity environment is possible for several months without affecting the A1 object. The use of an A1 Sealer PLUS or coating system will extent this period as it acts as a barrier between the humidity and the A1 object.

We have also tested A1 objects fully submerge under water and tested the quality of the top layer with the use of a Shore measurement (picture 1 and 2). Based on these tests an A1 object can be fully submerged under water for a period of 2 months without weakening the top layer. After this period the top layer weakens and the A1 will slowly dissolves in the water.